液体灌装过程中如何确保新瓶子/瓶盖形式快速无误地旋盖封口?

斯拉克集团的灌装旋盖一体机以其高效、精准、稳定的特点,为液体灌装行业带来了革命性的变化。它不仅提高了企业的生产效率和市场竞争力,更重要的是,它为消费者提供了更加安全、可靠的产品保障。相信在未来,斯拉克集团将继续引领液体灌装行业的技术创新和发展。

To ensure the durability of all toolings and avoid costly mistakes, your supplier must consider the Nominal Values of your machine’s settings for every new tooling study.

It is also important to record all your tooling designs, their associated containers, as well as the assembly of your machine during its lifecycle. This greatly facilitates tooling design regardless of the complexity of your bottles and caps.

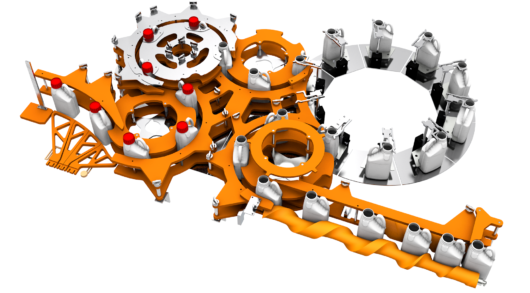

Your machine’s digital twin

Make sure that your supplier can deliver toolings year-round and respond very quickly when your productivity is impacted. As such, prefer a supplier with LEAN processes.

Choose a partner who not only knows your equipment but also your business constraints, to ease the implementation of your new toolings.

A competent technician on your machine will be able to check the proper adjustments of the tooling and can also provide operator training with the manufacturer’s manual.

If needed, the technician could also look for more comprehensive performance improvements.

To speed-up format changeovers, request compatible tool-free changeovers toolings.

“Puzzle” tooling

Light packaging and / or complex shapes can be damaged by generic toolings that are not adapted to your machine. Relying on properly toleranced 2D plans and 3D files is a must, but not enough to ensure quality circulation.

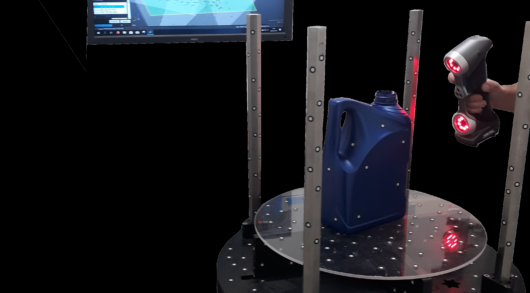

Bottles scanned

Scanning makes it possible to identify the hard points of your bottles and to measure their topload. This ensures the proper grip of your packaging and their smooth closing.

3D simulation of your moving packaging

All these studies help determine the ideal choice of anti-spin system and the fine adjustments of your capping turrets.

“ In the critical context of a new product launch, you must consider not only the technical skills of your supplier, but also its in-depth knowledge of your environment and your production equipment. To this end, working with the original equipment manufacturer of your machine offers you the highest quality and lowest risks.

“

上一篇:How does Serac help Greenfields dairy company to meet its new challenges?

下一篇:As little maintenance as possible is what we want in our equipment (Chobani)