The e-beam decontamination technology meets the ever-increasing health and safety requirements both with regard to consumers as well as operators, while at the same time reducing the environmental impact and space requirements for packaging production lines. It is because industrialists in the agricultural food sector are increasingly faced with this difficulty, that manufacturers such as Serac have developed decontamination solutions based on E-Beam technology.

The capability of the electron beams to efficiently destroy micro-organisms has been well known for decades and its reliability when used in a high-speed industrial production context has been confirmed in numerous applications, in particular for surface cross-linking of plastic materials.

Their use for the decontamination of packaging lines is however far more recent. It is associated with the development of a new generation of emitters, which are more compact and longer lasting, as well as the ground work undertaken by equipment manufacturers in the qualification of processes specific to this field of activity.

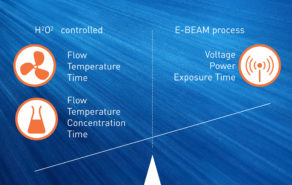

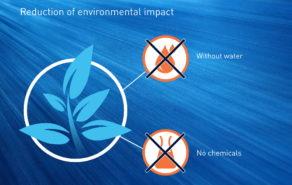

Without water or chemical products, E-Beam decontamination has a very low environmental impact. Once the process has been validated, this technology is far easier to control than the decontamination processes using hydrogen peroxide (H2O2) or peracetic acid. It is also a lot faster which enables a reduction in the space required for the decontamination module.

It thus offers all the advantages necessary to meet the needs and expectations of industrialists.

“ Safer and better for the environment, E-Beam decontamination technology has a promising future ahead of it in the aseptic packaging sector. “

-

Perfectly controllable physical parameters

-

Dry and “zero chemicals” sterilization

-

Bottle and cap decontamination

-

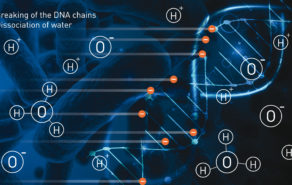

A double action on micro-organisms

-

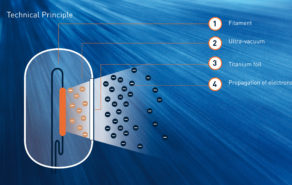

A technology based on the emission of a beam of electrons

上一篇:The Modulo filling nozzle: high flexibility in recipe changeover

下一篇:A two-compartment product tank offers new opportunities, especially for co-packers

相关文章

Application sectors

-

饮料灌装机

灌装机械科技的进步使冷饮、无菌饮料制造商 ...

-

牛奶灌装机

在过去的50年里,Serac在瓶装或杯装 ...